Case Studies

Heating & Hot Water

Cottam Brush – Heating system upgrade

About the client:

Cottam Brush was established in 1858 and has evolved from a small workshop in Samuel Cottam’s Sunderland home to a leading provider of trade, industrial, and specialist brushes across the world. The company has been running for six generations of the Cottam family and continues to work as a supplier for some of the world’s most prestigious companies across the subsea, engineering, and defence sectors.

Project background:

The team at Cottam Brush contacted us with particular heating requirements as the existing heating system within the business was outdated and inefficient, leading to inconsistent heating and high energy bills. In recent years an extension was added to the existing office space which was being heated with numerous outdated air conditioning units. Unfortunately, this was a high-cost and ineffective heating method for the business and its new space. To maintain a comfortable working environment for their employees and reduce operating costs, Cottam Brush made the decision to upgrade this heating system.

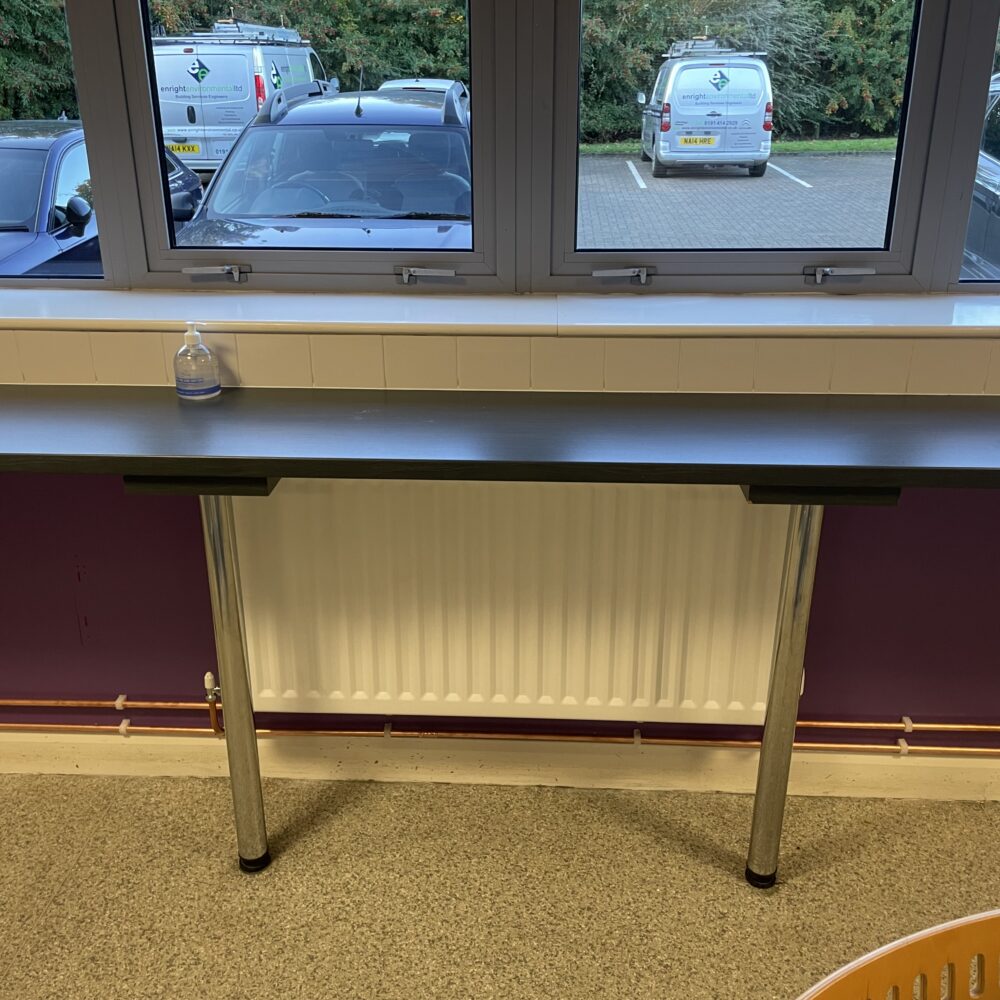

Updated radiators inside Cottam Brush boardroom

Project solution:

To begin this project, our team carried out a thorough site survey of the Cottam Brush facility to scope out the heating requirements of the building. We recommended the installation of a new high-efficiency system boiler along with seven new double-panel convector radiators, thermostatic radiator valves and associated pipework, in addition to the existing radiators in the building. The system boiler was chosen for its ability to maximise energy efficiency and provide reliable heating without the fear of a boiler breakdown in the colder months. The double panel convector radiators will allow the extension area, consisting of the staff canteen, boardroom, and meeting room, to be heated effectively.

The installation project was planned and executed by our team of skilled engineers who replaced the old boiler with a modern, energy-efficient model, installed new pipework to feed the new double panel radiators, and strategically positioned the radiators. All pipework was appropriately insulated to increase energy efficiency, and a magnetic filtration device was installed to protect the boiler and maximise the system’s lifespan. The installation was completed on schedule, causing minimal disruption to Cottam Brush’s daily operations.

Updated radiators and pipework

Project result:

This installation had an immediate and significant impact on Cottam Brush’s building. The project allowed employees to experience a consistent and comfortable working environment, without the worry of costly and inefficient air conditioning units. The new system significantly reduced energy consumption leading to lower heating costs for the business, and the upgraded heating system operated reliably, minimising downtime and maintenance.

Cottam Brush was highly satisfied with the quality of work and the professionalism of our team. This project has transformed into a partnership and we will be providing ongoing maintenance and other mechanical service requirements for Cottam Brush, ensuring their heating system and other gas equipment continue to operate at peak performance.

Managing Director, Alan Crook, had this to say about the project –

“Enright has recently installed a new boiler and heating system in our offices at Hebburn. Ellis and the team were professional and efficient throughout, from quotation to installation to completion. The work was carried out with minimum fuss and disruption, and we were delighted with the result.”

New boiler system

Boiler system rooftop flume