Case Studies

Energy Efficiency

Raytec – Energy efficiency solution

About the Client:

Founded in 2005, Raytec are specialists in LED lighting. Every Raytec product is designed and manufactured in Ashington, Northumberland in their 30,000 sq. ft. factory. Raytec’s lighting products are shipped to distributors around the globe and fall into four main categories, such as:

- Hazardous

- Industrial

- Transport

- Security.

“LED lighting saves energy and reduces the users’ Carbon Footprint. Given our “green products” and ethical nature, we felt it only right to become Carbon Neutral and then work towards Carbon Neutrality for our clients. To become Carbon Neutral, firstly we measured our Carbon Footprint for Scope 1, Scope 2, and Scope 3 (business travel) emissions for 2022. Secondly, we scoped out some energy reduction projects and calculated the expected reductions. Our Carbon balance has been offset by investing in reforestation schemes in both Uruguay and Northumberland.”

Project Background:

From an early stage, Raytec worked in partnership with Enright Environmental, together we established that the most significant means of energy reduction was to improve the heating system and controls. Raytec had some great theoretical knowledge but lacked the practical know-how of what was possible and what can be put in place. We went through a couple of iterations with Enright before deciding on the best, and most cost-effective solution which we have projected should reduce gas usage by 16% and has a simple payback of less than 3 years.

Project Solution:

The project fell into three distinct categories. The first of which was to install 4no. motorised backdraught dampers internally over the existing roof-mounted extract fans. Prior to this project, the extract fans were always open to the outside atmosphere, meaning that significant amounts of heat were being lost through the roof penetrations. Saving this heat was step 1 of the project.

The second step of this project was to be able to utilise the warm air saved by the backdraught dampers, the best way to do this was by re-distributing the warm air collected at a high level back to the ground level of the factory via destratification fans. Raytec already had 3no. destratification fans at a high level which was a good start, but 3no. more destratification fans were installed and the 3no. existing were relocated to provide maximum efficiency and coverage across the factory. Re-distributing this warm air now means that the heating equipment won’t be operating as often as it was, ultimately saving Raytec money in energy costs.

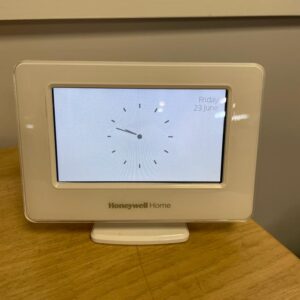

The third and final step of this project was to provide Raytec with an updated modern control system allowing them to remotely control and monitor the usage of their warm air heating, office wet heating and domestic hot water equipment whilst on or off-site using an app on a mobile phone or tablet.

Original extraction fan

Updated extraction fan

Project Result:

As of June 2023, Raytec is now Carbon Neutral, but they don’t plan on stopping there.

Raytec has other energy-saving projects planned such as Voltage Optimisation & Secondary Glazing and will soon be engaging with their supply chain to measure and reduce more of their Scope 3 emissions.

Here’s what Raytec’s Simon Taylor (Head of Operations) had to say about working alongside Enright Environmental on this project – “Working with Enright was a rewarding experience from the ideas stage right through to installation and commissioning. Installation required significant high-level work. This was a challenge whilst trying to run a factory at the same time and was only possible via the close team-based approach established between Raytec and Enright.

In summary, Raytec would highly recommend Enright as a partner for such projects. We are delighted with the project scope, execution, and outcome. We look forward to measuring the energy and carbon reductions through the next heating season.”

New control system